Support - Tracker S

Heliomotion Tracker S was produced between 2008-2016 and used for TC-1200 and PV-2 units. If a Tracker S unit becomes worn out it can be upgraded to the latest model (Tracker Z). If a Tracker S unit does not follow the sun please go through the troubleshooting steps below.

![]()

![]()

S Support

Use a volt meter to confirm that the 24VDC transformer supplies 24VDC to the solar tracker’s circuit board. If the transformer is powered but doesn’t produce 24VDC it is most likely broken and need to be replaced with another 24V transformer able to handle 6A of current. The other possibility is that a short circuit has appeared on the circuit boards, causing the voltage to drop. Visually inspect the circuit board for signs of water ingression to make sure the cause of the voltage drop is not due to a short circuit.

Try turning the tracker by hand using the panels as a lever. If the tracker can be rotated by hand the gear box is worn out and the tracker needs to be upgraded to a later model.

If 24VDC is supplied correctly and the tracker cannot be rotated by hand it’s likely that the circuit board needs to be replaced. Use the contact form to order a circuit board. The latest circuit board is mounted on the backside of the tracker’s column and combines the functionality of the two previous circuit boards into one.

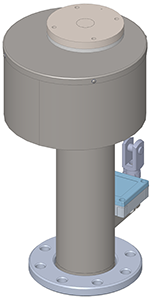

Support - Tracker XL

Heliomotion Tracker XL was produced between 2017-2018 and used for PV-2, PV-3 and PV-4 units. Spare parts for Tracker XL are available for self-repair. If a Tracker XL unit becomes worn out it can be upgraded to the latest tracker model. If a Tracker XL unit does not follow the sun please go through the troubleshooting steps below.

XL Support

The 24 VDC transformer may have broken. Use a volt meter to confirm that the 24VDC transformer supplies 24VDC to the solar tracker’s circuit board. If the transformer is powered but doesn’t produce 24VDC it is most likely broken and need to be replaced with another 24V transformer able to handle 2.5A of current. The other possibility is that a short circuit has appeared on the circuit boards, causing the voltage to drop. Visually inspect the circuit board for signs of water ingression to make sure the cause of the voltage drop is not due to a short circuit.

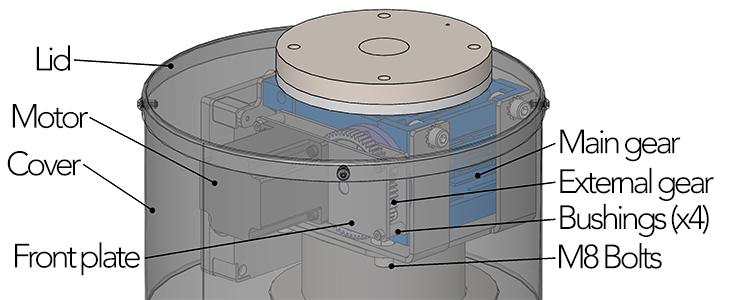

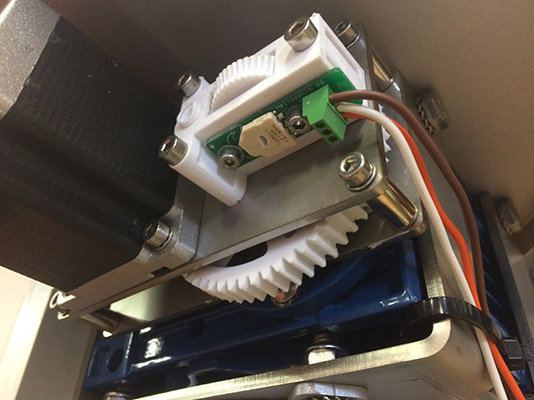

The External gear may be worn out. Open the Cover with the M3 hex key to see the external gearbox that connects the motor to the main gear. If the gear can be rotated (by hand or using Heliocom) without the Main gear turning, then the gear needs to be replaced. Replace it by temporarily removing the Front plate using an M4 hex key. Note that the hole for the gear in the Front plate may need to be drilled in order to fit the replacement gear.

A replacement External Gear for Tracker XL can be 3d printed using the following STL file External Gear (Tracker XL). For smaller units (PV-2/PV-3) the material can be plastic (ABS), for larger units (PV-4) it’s recommended to print it in metal (Aluminium). For instance, Nora Chen (email: [email protected]) provides a 3d printing service with global shipping.

The pinion that attaches to the motor is the same for Tracker XL and Z. Link to pinion STL is available on Tracker Z support page.

The Position sensor may be damaged. Use Heliocom to determine whether the sensor updates correctly when the tracker is manually rotated. If the sensor is very inaccurate it is likely because of water ingression. Apply the silicone fix under Recommended fixes and the sensor should dry out and become accurate again after about a week of dry weather.

If the sensor is unresponsive, and doesn’t change when the tracker is manually rotated, it may have been damaged by wind. The sensor then needs to be replaced with the newer Tracker Z position sensor as shown below.

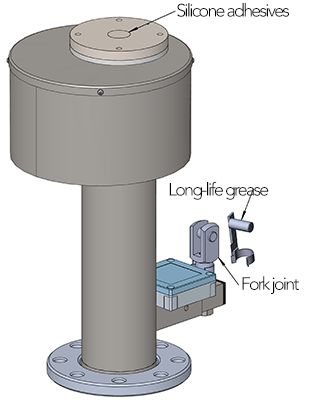

Water Protection

At the top of Tracker XL there’s a joint between the flange and the shaft. Excessive wind can damage the seal at this joint causing water to reach the position sensor at the bottom of the shaft, which may temporarily decrease accuracy of the sensor or damage it. To avoid this it is recommended to apply a silicon adhesive to the joint. Clean the surface beforehand. The joint is accessible without having to remove anything.

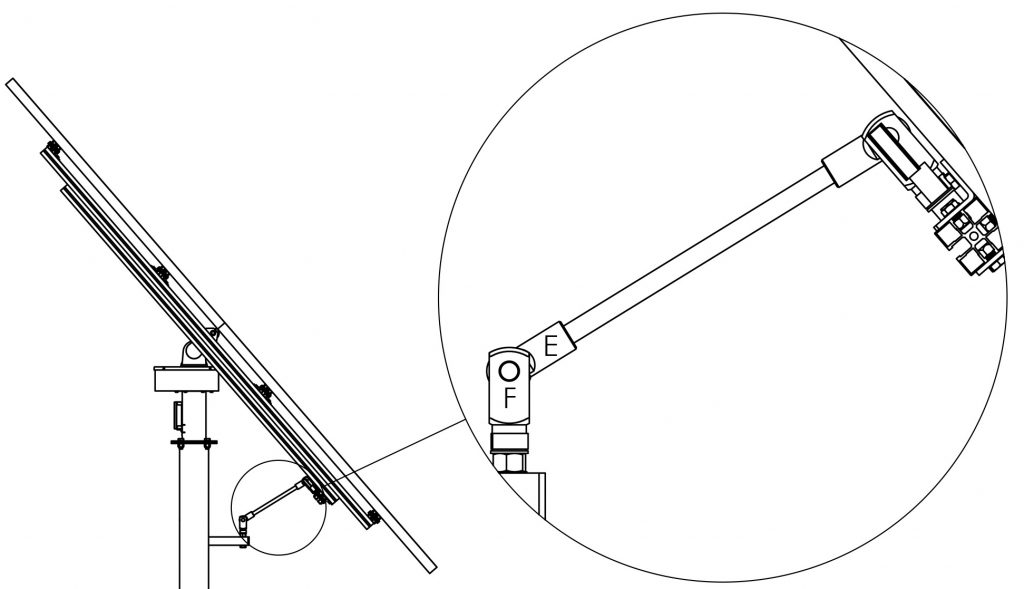

Fork Joint Lubrication

It is recommended to apply long-life grease to the threads of the clevis eye (E) and the fork joints (F) as well as to the rotating shaft that locks the clevis eye to the fork joint. This reduces friction which can otherwise cause noise to occur during rotation. Depending on weather, this process may need to be repeated every few years to keep friction low.